2014 / 2015

Window Production Simulation

Graduation year

Customer

SimPlan (Dipl.- Ing. Peter Rachinger), Internorm

Graduates

Hötzmanseder Manuel

5AHWII

Kapfer Erwin

5AHWII

Supervising tutor

Rachinger Peter

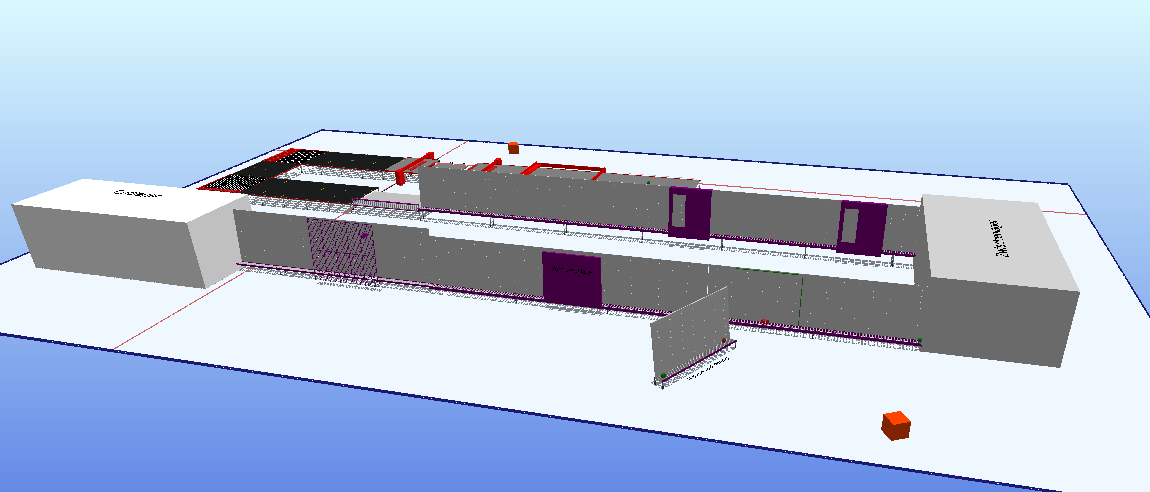

Simulation application for window glass production

The objective of this software was to simulate the individual steps in the window glass production process and present them in a clear graphical display.

Glass panels with a total area of up to 20 m² are ‘broken’ into smaller elements along pre-cut breakage lines to ensure the lowest possible amount of material wastage. The glass is then subsequently washed and examined for errors, dirt or other impurities. Damaged or sub-standard material is immediately removed and the remaining glass panes are transferred into an interim storage area.

Connecting frames are set between glass panes and these elements are transferred to the pressing and gas filling station. The space between the panes is filled with gas and the unit pressed together. The whole double glazing element is then sealed with a polyurethane adhesive.

Finally, the finished element is transferred to the final storage hall to await delivery.

With the assistance of an OPC server the different control functions in the sealing system and the visualisation of the plant data could be set up. This allowed numerous adjustments to be simulated and control over the functions of the sealing system could be constantly monitored.

During the simulation, a number of basic elements were developed and saved in the databank which could serve as a reference library for future projects.

Deutsch

Deutsch Español

Español