2017 / 2018

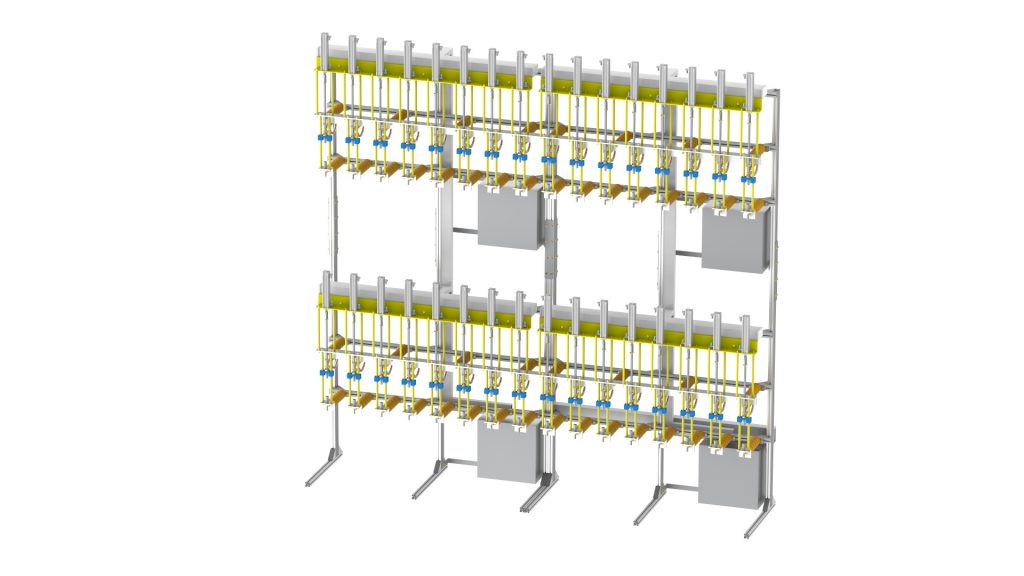

Contact switching system

Graduation year

Customer

COIL Innovation GmbH

Graduates

Radinger Alexander

5AHMBA

Hartl Stefan

5AHMBA

Pöchtrager Thomas

5AHMBA

Springer Stefan

5AHMBA

Supervising tutors

Kiesl Walter

Project description

This project includes the planning, construction and the commissioning of a contact- switching station in the company Coil Innovation GmbH in Eferding, situated in Upper Austria.

Until now, operators had to go into the danger zone to manually connect condensers, which were specifically calculated for each test. Consequently, the aim of this project was to develop a switching system which automatically reacts a new condenser bank for the acoustic test procedure. The user-oriented platform allows workers to operate the switching systems from any company computer which ensures that employees do not have to put themselves in danger anymore. Furthermore, a lot of time can be saved due to the short switching times of the cylinders. On account of the acoustic project, more tests can be implemented in parallel (high-voltage, warm-up, etc.).

Design, production and test procedures are implemented at the company in Eferding. Before reactors are contributed to clients, they are tested under operating conditions. One testing procedure, the acoustic test, has become significantly important due to customer demand. These requirements arise as dry-type reactors are increasingly used in residential areas where the volume level plays a significant role. In order to simulate the demands under real conditions, different capacities of the switching system are tested. Those capacities are dependent on the reactor’s form and construction as well as the testing frequency. During the test the volume is measured, and the data recorded in a diagram. The acoustic behaviour of the reactor can be directly read from this curve.

Until now, operators had to connect the condensers manually, which were specifically calculated for each test. Consequently, the aim of this project was to develop a switching system which automatically reacts a new condenser bank for the acoustic test procedure. The big advantage is that the system saves a lot of time. The user-oriented platform allows workers to operate the switching systems from any company computer which ensures that employees do not have to put themselves in danger anymore. Furthermore, a lot of time can be saved due to the short switching times of the cylinders. On account of the acoustic project, more tests can be implemented in parallel (high-voltage, warm-up, etc.).

Deutsch

Deutsch Español

Español